contact us

contact us

If you would like to leave us a comment please go to

Contact Us

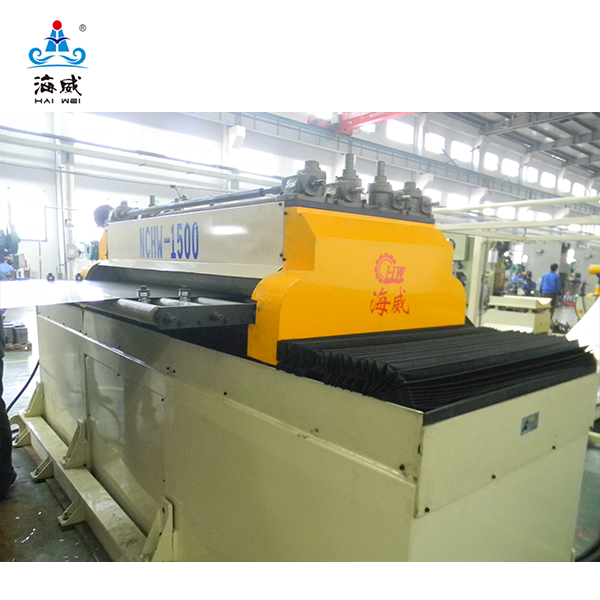

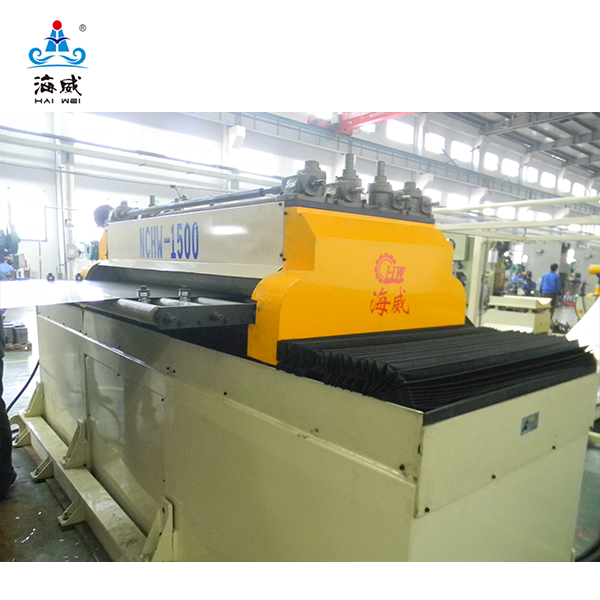

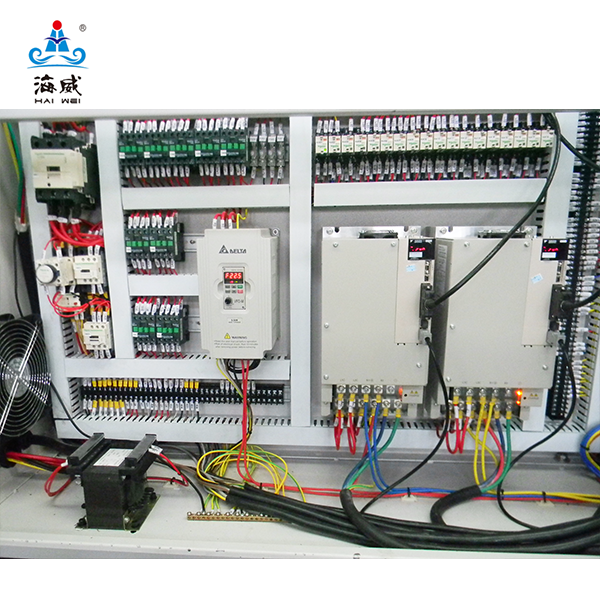

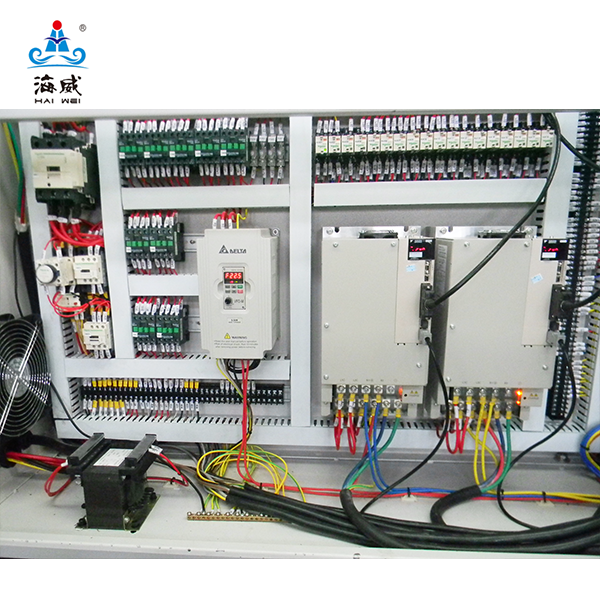

PRODUCT DETAIL

Features