contact us

contact us

If you would like to leave us a comment please go to

Contact Us

3 in 1 uncoiler straightener feeder is a very popular coil feeding line for punch machine used in metal parts stamping industry. Dongguan City HAIWEI Intelligent Equipment Incorporated Company, (the following abbreviate of “HAIWEI”), is one of the leading manufacturers of automatic coil feeders in China, we have sold many sets such machines to abroad, so it is important to know how to maintain the equipment and how to solve the problems in case that the machine failed to work.

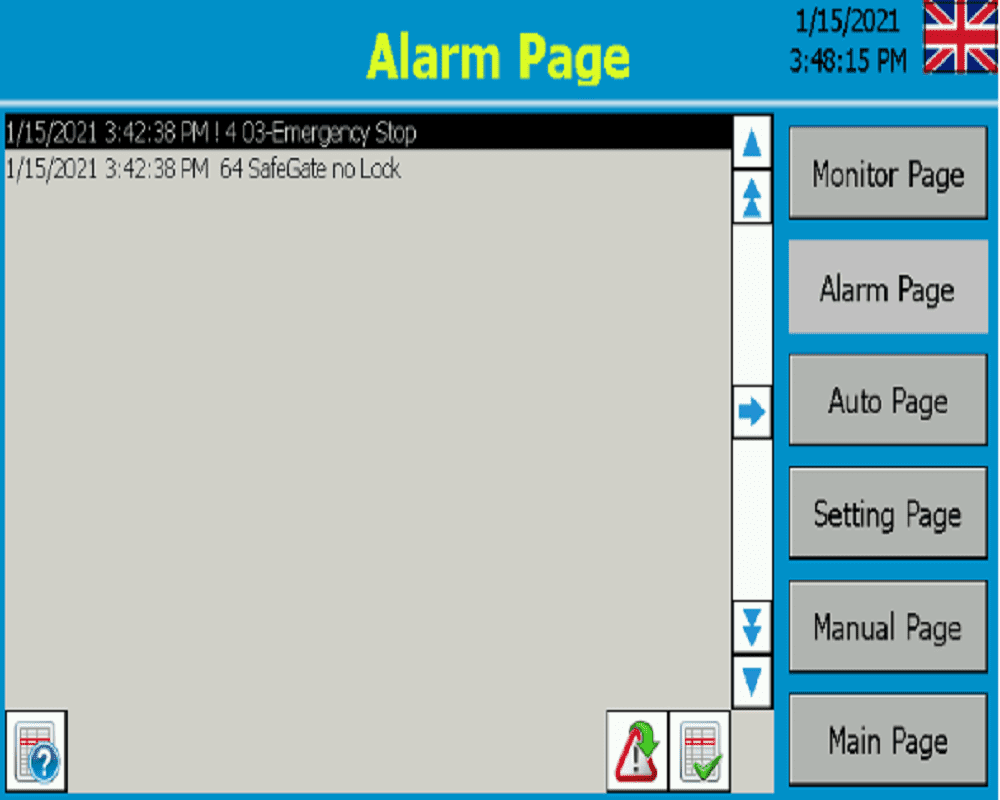

It not only combined decoiler, straightener and servo feeder’s mechanical parts in one machine, it also combines pneumatic part, electrical parts and hydraulic parts in one machine. So it can indicate the failure information in HMI’s alarm page and failure information indicated in servo drivers, so the operator can find out the problem after checking these alarm information. Moreover, it also sets Emergency alarm button and lamp, it can alarm if it occurs emergency stop, servo malfunction, inverter malfunction, material use up, set value error etc. (refer to following image)

It can also check input signal and output signal of PLC in I/0 monitor page, it is convenient for us to judge and manage the malfunction.

Question No. 1: Why the power lamp isn’t light?

Answer: a). Check if it connect well and correct of AC power.

b). Master switch is ON or off. circuit breaker is On or Off. duct pilot is OK or Not.

Question No. 2: Why can’t clear up the alarm hitches?

Answer: a). Mistakes at data settings.

b). Emergency button is ON or material is use out.

c). Accessories hitches: servo motor or encoder or servo motor driver or inverter break out, if this, please solve the problems by the experienced electrician.

d). Turn the button to auto but the button drew back.

Question No. 3: Why decoiler can’t payoff strip in “Auto model”?

Answer: a). Please check if there is problem of upper and lower loop control sensors; if there isn’t barrier between sensors and reflect board, sensor lights are one is red, the other is green, on the contrary, if there is barrier between sensors and reflect board, all the sensor lights will switch to green.

b). Check if there is output signal at “Output monitor” page, if yes, please check related relay at electric board.

c). If relay runs in normal condition, please check if there is 0-10v output signal at potentiometer.

d). Check if there is problem of press follow function.

Question No. 4: Why the decoiler can’t work automatically?

Answer: a). Check function was cut off or not, check if it’s light of the electric eye loop control device.

b). No PLC output in I/O image. If not, check the electric relay.

c). The electric relay is OK, check if there is 0-10V voltage signal in potentiometer.

d). Check the press arm wheel speed tracking system.

Question No. 5: Why decoiler payoff can’t stop?

Answer: Failure at electric eye loop control device.

Question No. 6: In HMI’s alarm page indicated information of Mandrel inverter alarm, what’s the problem?

Answer: Please check if press arm pressing coil too tight causing decoiler’s mandrel encountered much resistance then it give alarm in servo driver and indicate alarm information in HMI. Solution: Reduce the fluid controlling press arm’s in hydraulic station (for the condition driven by hydraulic cylinder of press arm), reducing air pressure in decoiler’s air filter.

| Check or maintenance term | Item | Contents |

| Maintenance term in irregularly scheduled | Equipment cover‚ Touch screen | Clean the equipment cover‚ Clean the touch screen |

| Daily check and Maintenance term | decoiler’s loop control function; ‚ emergency stop function | Check if loop control sensor work very well; ‚ Check if the emergency buttons work very well. |

| Weekly check and maintenance term | Drive gears of the straightener feeder part; ‚ Material width adjust & guide device at straightener feeder’s entrance; ƒDecoiler’s Mandrel expansion part. | Check if there is enough grease in movable parts; ‚ Fill oil to the gears; ƒFill grease to decoiler’s mandrel expansion parts. |

| Monthly check term维修项目 | Decoiler’s chains; ‚Synchronous belt of the straightener feeder; ƒPress wheel driving chain of the decoiler; ④ Bearing’s position of the decoiler’s main axle; ⑤ Air filter. | Add grease chains; ‚ Check if synchronous belts are in good tension condition; ƒAdd grease on bearings of the decoiler’s main axle; ④ Check if the screws are loose or not. ⑤ add lubrication oil in air filter and clear water and impurity in air filter |

(3)Mandrel expansion sleeve

(4)Pass line height driven motor chains inner of straightener feeder base.

(5)Straightener feeder release bracket

(6)Gears in straightener feeder part

(7)Press arm wheel chains

2. Maintenance in hydraulic station-change hydraulic oil part.

2.1 For hydraulic station part

① It ‘s better to change new 46# hydraulic oil every 12-18 months.

② Please also clean filter strainer in hydraulic station when change new oil.

③ Ensure motor runs in clockwise as marked label running direction as follows:

3. For Hydraulic pressure

It’s better to keep hydraulic pressure not more than 12MPa, normal working pressure is 8-10MPa.

Warning: If pressure is over 12MPa, it may cause coil car’s gear pump crack, hydraulic cylinder crack, hydraulic valves damage etc.

4. Maintenance for air filter part

4.1 Add ISOVG32 lubrication oil in air filter’s oil cup (right cup) which was used to provide lubrication oil to pneumatic spare parts, such as pneumatic cylinders, pneumatic solenoid valves etc.

4.2 Clear stocked water and impurity in air cup (left cup), filtering compressed air and stock water, impurity in this cup, it has to Clear stock water and impurity once every month.

5. Check loop control sensor’s work condition.

5.1 The upper and lower light should be one lamp green and one lamp orange when there is no barrier between sensor and reflect board. Or please adjust the sensors.

5.2 The light will switch to green when there is barrier between sensor and reflect board.