contact us

contact us

If you would like to leave us a comment please go to

Contact Us

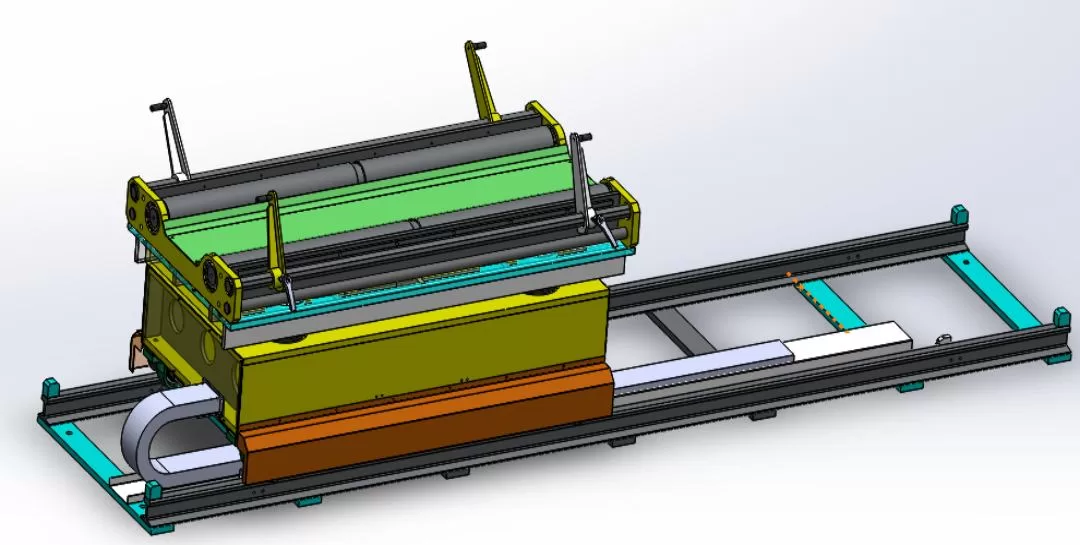

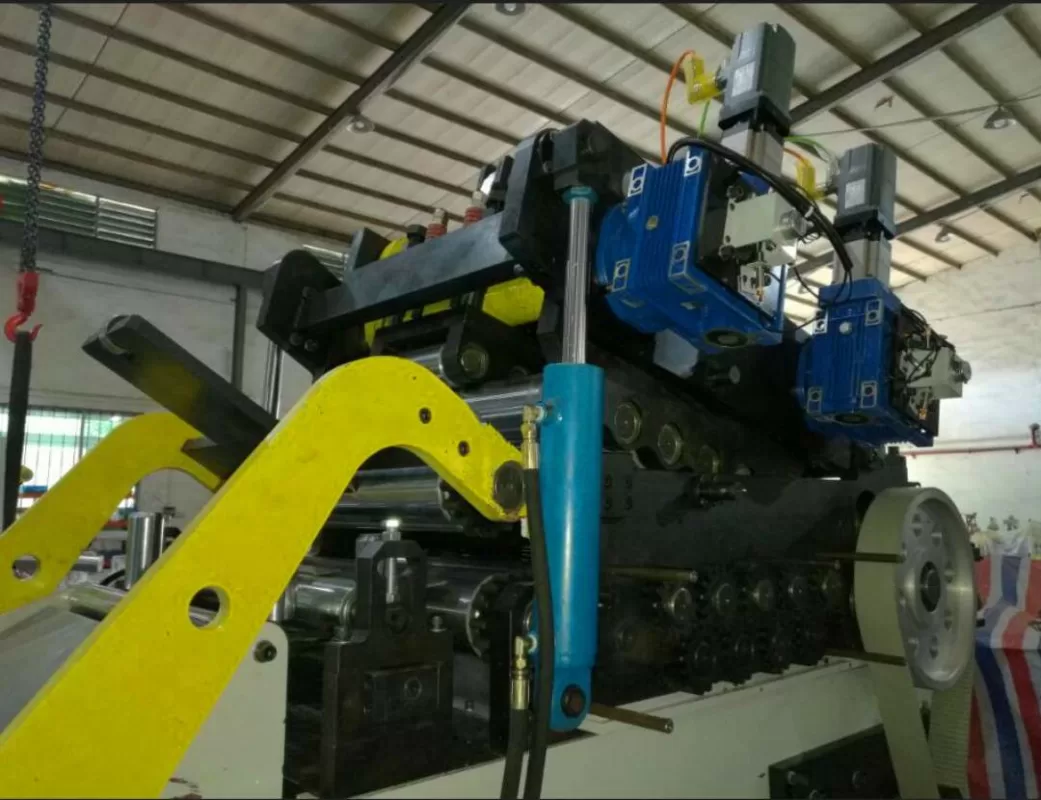

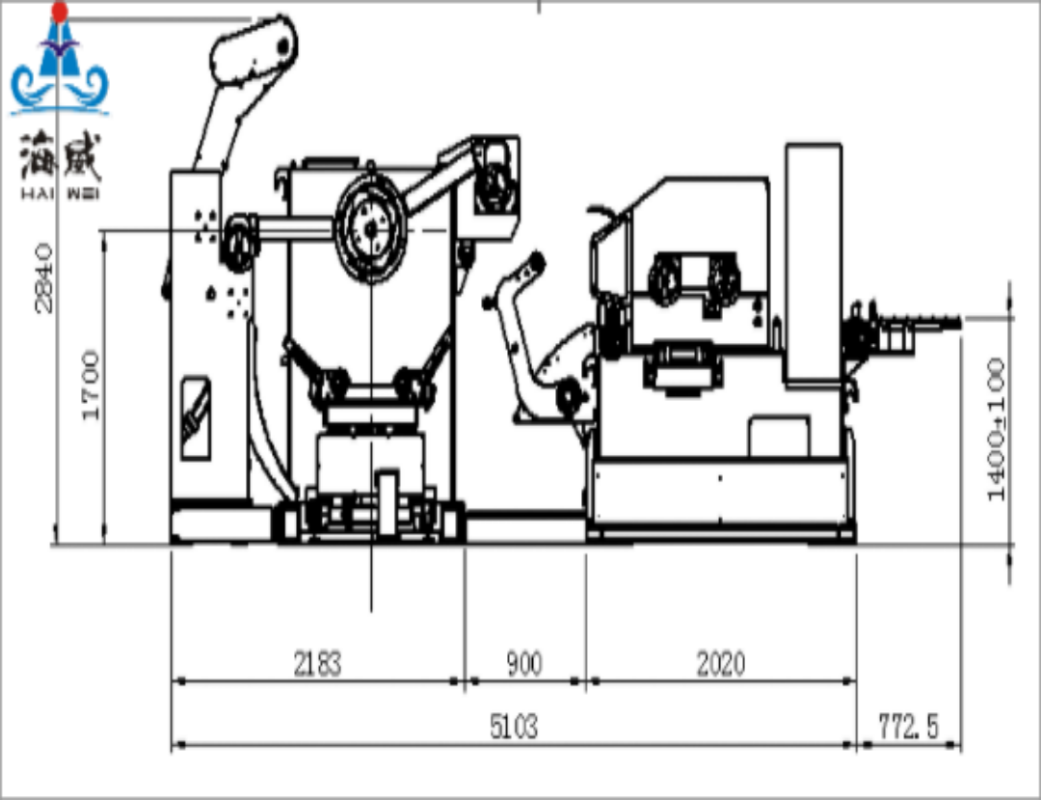

Product Name: NCHW3-800A high-strength plate 3 in 1 uncoiler straightener feeder with punch press for automotive parts stamping blanking line. It contains decoiler, press arm, limit arm, support arm, straightener, coil car, feeder, and hydraulic shear. All the parts are integrated into one servo control system. Haiwei steel coil straightener has high-precision feeding performance and accurate straightener performance wjjhile ensuring operational safety.

The 3 in 1 uncoiler straightener feeder has a wide range of applications. It can be used in the stamping industry of various metal coils with materials ranging from 0.6mm to 6.0mm. It not only improves the production efficiency of the enterprise, but also improves the product quality.

Material can be processed: High tensile stell, SS. CR, HR, GI etc,.

The 3 in 1 uncoiler straightener feeder is divided into thin, medium, thick and high-strength plate models. They are classified according to the material thickness. When the 3 in 1 uncoiler straightener feeder feeds materials with a thickness of 0.5-4.5mm mainly used in automotive parts stamping, electrical components, seats, elevators and motor stator and rotor stamping industries. Materials 1.0-8.0mm and 10mm ultra-thick materials are mainly used in auto parts stamping, curtain wall industry, storage shelf punching, locks, hinges, gaskets and other stamping industries.

In actual production, the 3 in 1 uncoiler straightener feeder can be customized to add auxiliary devices according to the actual production needs of customers. Such as: used for moving coil to spindle of uncoiler smoothly. Simple and convenient operation, saving time.

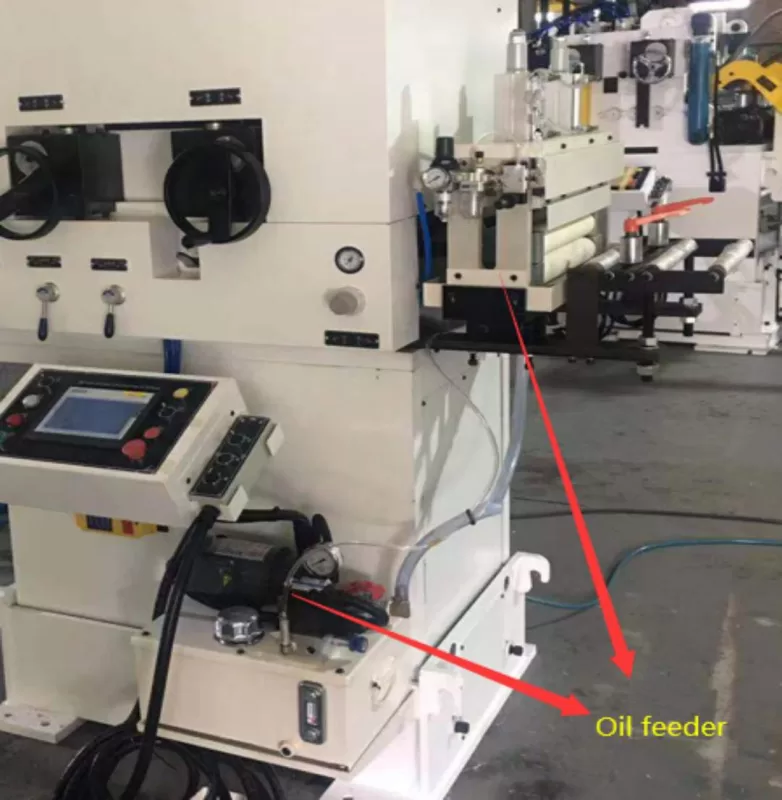

Strip oil feeder also called strip oil lubrication system which can single/double side painting oil uniformly, oil quantity can be adjusted, Intermittent oiling, the oiling time can be set. oil can be used circularly. Redundant oil can be oil returning system to return, via filter screen then through oil pump to supply oil mass, not waste of oil.

Use for shearing material head/end, and blanking too. Mainly use for thicker or high strength material, which is not easy to shear manually.

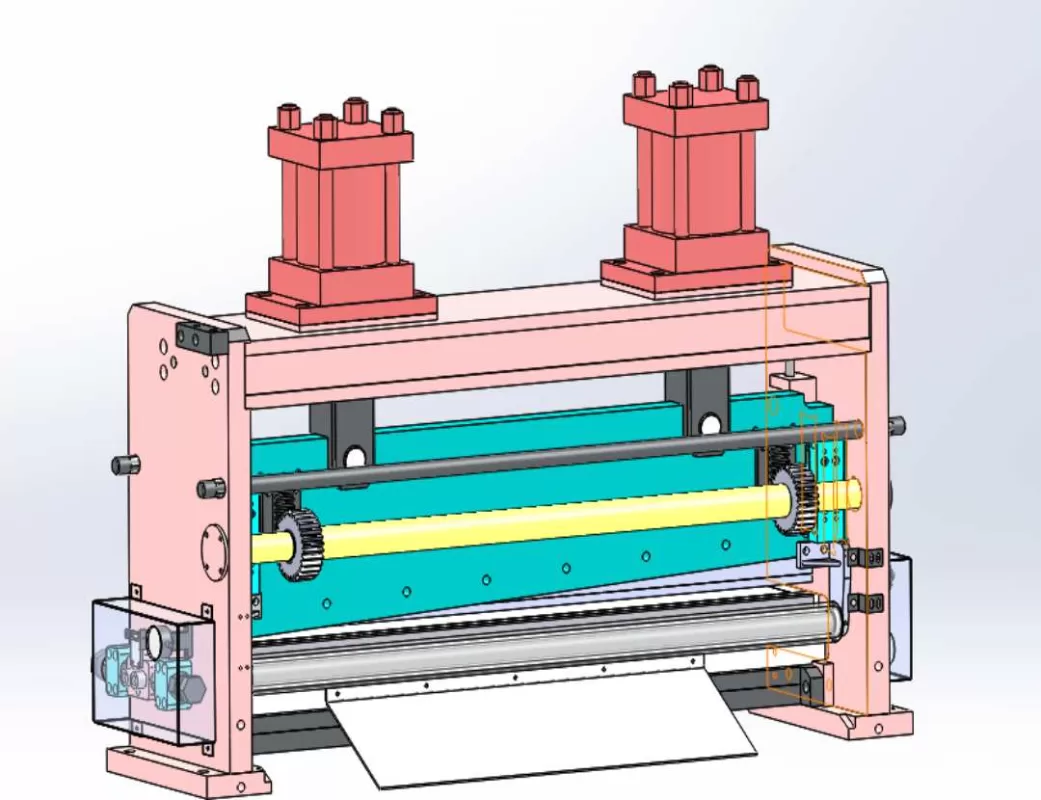

It adopts one-key opening function, just press button on the operating panel thern can open the upper straightener-feeding rollers head to clean rollers. While close straightener feeding rollers, also adopts one-key closing function, which is very easy operate.

The 3 in 1 uncoiler straightener feeder has a high degree of automation. From loading, uncoiling, leveling, feeding to shearing, it can be completerd by one machine. Humanized operation, the operation of the 3 in 1 uncoiler straightener feeder machine can be completed on the touch screen without excessive sdjustments, which is convenient and fast.

1) 3 in 1 uncoiler straightener feeder saves space and increase productivity. Compact structure, combined straightener feeder head. The total length of the machine boby 3.2-6.0 meters, compact structure, occupies littlee space.

2) High rigid mechanical design sturdy construction, and high power output to secure proper straightening and feeding during the speed increasing efficiency.

3) The housing-type structure is specially designed for high-strength plates, and the upper and lower leveling rollers have reinforcement structures to ensure that the stress relief effect meets the standrad.

4) Coil Material Entry support Assembly can bring the material into pinch rollers Automatically to save man power and increase safety,

5) Full set of Siemens servo control system: high-precision feeding; humanized design and safety protection system etc,. Convenient for operating.

6) Manual and automatic working modes, can match the stamping press properly.

7) Feeding speed, feeding pitch, and feeding steps are programmable. Meet all production needs.

8) Multipe protection systems, low failure rate: mature procedures to ensure the stability of the system under long-time operation:

① Motor overload protection function.

② Abnormal material loop detection stop functio.

③ End material detection stop function, to ensure the failure of the 3 in 1 uncoiler straightener feeder system operation.